Technological equipment designed for field realities.

START ON THE RIGHT FOOT WITH A PROOF OF CONCEPT

A good number of our successful projects start with clients presenting functional prototypes. When Soft dB sought our assistance, they already had a functional prototype (P0) that met basic requirements but faced challenges in terms of portability and robustness. While these prototypes meet basic performance criteria, they often lack crucial features and essential details for repeatable and affordable manufacturing. They serve as an excellent starting point for our team and significantly contribute to mitigating risks associated with development.

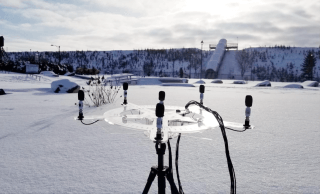

DESIGNED FOR RELIABLE OUTDOOR MONITORING

The majority of products crafted at Advanta are tailored for harsh environments and challenging weather conditions.

Soft dB sound radar systems are no exception, as they are typically installed outdoors, adjacent to noise and sound sources. They mostly operate in rental and service capacities. Therefore, prioritizing durability, reliability, rapid deployment, and ease of transportation are integral features we carefully consider during the design process.

CONFIGURATION CHALLENGES

For transportation purposes, the product needed to swiftly collapse or disassemble. Once installed, assembly should be quick to accommodate rental needs and effectively mitigate noise during windy conditions. In the initial prototype, with microphones installed on-site, we investigated the concept of integrating them onto the device in a manner where they fold over each other without overlapping.

TWICE THE CONFIGURATIONS, TWICE THE FUN !

When conceptualizing a product with multiple states, we must factor in the time needed for modularity. This entails considering the product in two distinct positions to prevent interference between components. Additionally, we need to contemplate how the product is utilized in both scenarios, including manipulation during collapse and extension, as well as cable management in each state. Moreover, we must assess whether the collapsed form fits inside a standard carrying box and ascertain the requirements for such a box, enabling us to design accordingly with market-available options rather than custom solutions.

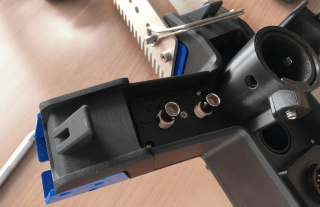

MASS PRODUCTION IS NOT ALWAYS A REQUIREMENT

Due to the anticipated quantities, our aim was not to develop something for mass production, but rather to swiftly design a solution without any tooling needs. Utilizing 3D printed components alongside shelf hardware and laser-cut metal parts was chosen to minimize the investment necessary for field deployment. While one might view this product as a high-end, duty field-testing prototype, its purpose remains limited to that role, thus simplifying the design to avoid unnecessary complexity.

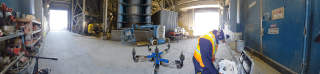

TAYLOR-MADE FOR FIELD SERVICING TEAMS

Designing a product for a service company versus creating one for direct sale to clients can significantly influence the design costs. When selling a product to clients, you relinquish control over its usage, perception, and handling, potentially impacting its performance and longevity. In contrast, as a service company employing your own product, you retain the ability to train staff on proper usage, maintenance, and storage, thereby exerting influence over its lifespan and user experience.

TAYLOR-MADE FOR FIELD SERVICING TEAMS

While this may involve sacrificing certain aesthetic qualities typically associated with consumer products, prioritizing functionality, ease of deployment, and durability remains paramount. Soft dB exemplified this approach by utilizing 3D printing manufacturing processes to create robust parts, foregoing the polished appearance of injection-molded counterparts. Ultimately, what matters most is that the product fulfills its intended purpose reliably and efficiently, regardless of its aesthetic appeal.

THE POWER OF A

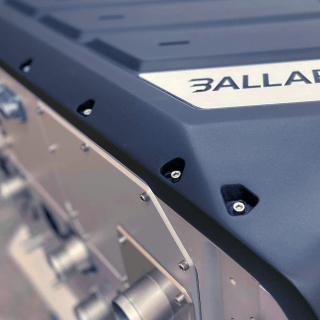

REALISTIC IMAGE

Each of these four images has been designed using a 3D model integrated into a scene within rendering software. They are essential tools for visualizing the product within your team and for client presentations. These images can be produced during the design process. However, as the product approaches the production phase, the level of detail in your 3D model becomes optimal for generating realistic images. These renderings quickly transform into valuable assets for your marketing team, enabling them to effectively promote a product that has not yet been physically realized.