THE INSPECTION OF SEWER NETWORKS ENTER A NEW ERA

Innovation & Collaboration

During our meeting with Can-Ex, significant challenges were identified, including adapting to various pipe sizes and improving camera integration. The client sought a comprehensive solution for inspecting pipes of different sizes, leading to significant modifications in our initial design.

A "NINJA" TECHNICAL CONCEPT TEAM

The close relationship with Can-Ex was exceptional, fostering a trusting environment among development teams conducive to open exchanges. The client's contribution to defining needs and objectives was invaluable, enabling the sharing of bold ideas and the establishment of a common vision. The speed of execution and the focus of our teams allowed for a swift transition from mechanical validation prototype to visual concepts, and then to a functional prototype. This collaboration resulted in the creation of an innovative and validated product, demonstrating the effectiveness of our integrated approach.

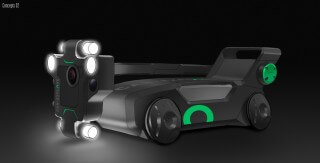

360° TECH IN A WATER POWERED ROVER

A key aspect of the ZipCam project lies in its technological innovation. Powered by water pressure, the 360° camera provides a unique approach to visual inspection. The challenge of making this technology waterproof has been successfully addressed, paving the way for a solution that pushes the boundaries of pipe inspection.

Management of TECHNICAL Challenges

The encountered difficulties included issues with the wheel changing system and camera integration. Malfunctions in the schedule also complicated the smooth progress of the project, as it took place over a relatively short period, from October to April. The development of the battery was also a technical challenge faced by the team. The clever design, allowing easy and quick access to the battery, requires a delicate balance between practicality and durability.

ADJUSTMENT MECHANISMS AND INGRESS PROTECTION

The heart of the ZipCam project lies in the innovative mechanisms, highlighting the complexity of the design. The mechanisms have been meticulously developed to ensure easy use and resistance to extreme conditions. Although IP certification was not pursued, special attention was given to the robustness of the mechanisms against the elements.

THE MARKETING TEAM MADE IT LOOK FUN

The Can-Ex team produced an excellent video demonstrating the product in its context and highlighting the challenging environment in which this inspection tool operates.

Typically, our task involves designing products capable of withstanding extreme conditions should they arise. This was one of the rare instances where our team had to intentionally design a product to undergo such endurance testing daily.