Take 50 pounds off. Move without limits.

A Biomechanics-Centered Challenge

At Advanta, we tackle technical challenges with both rigor and creativity. The development of this dynamic lumbar brace was driven by a complex health issue: evenly reducing up to 50 lbs of pressure on each lumbar disc. The device provides mechanical support while seamlessly integrating into the user’s daily activities.

Fast Iterations

and Improvement

The close collaboration with Corset St-Francis team who was present at every stage of the project; greatly enriched our process. By carefully considering his precise feedback on tested prototypes, we were able to quickly adjust components, optimize performance, and refine the product in an efficient iterative cycle. This constant exchange between real-world use and design allowed us to shorten development timelines, control costs, and deliver a solution perfectly aligned with a clear, concrete, and shared vision of use.

A Collaborative

and Agile Design

The key to this project lay in the synergy established between Corset St-Francis, Tactix (experts in innovative and durable textile solutions), and our team. Together, we worked in close collaboration—discussing, revising, and fine-tuning every decision to ensure perfect functional harmony between the mechanism, textile belts, and user comfort. This holistic approach was essential to ensure a coherent product that is both high-performing and ergonomic, while remaining true to the client’s vision from the very beginning.

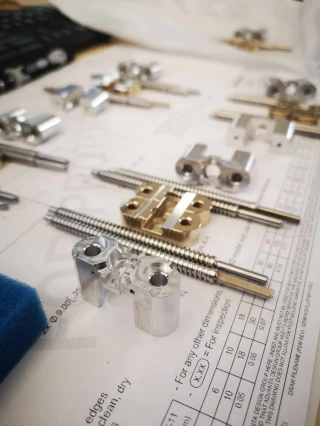

Design of Rigid Components

Advanta designed the rigid plastic parts forming the structure of the brace, meeting strict requirements for stability, compactness, impact resistance, and long-term durability, while integrating seamlessly into the product’s overall architecture. These parts underwent internal immersion and impact testing to ensure user safety (non-flammability and prevention of hazardous shattering upon breakage). Another challenge involved concealing the cables powering the brace. In collaboration with Tactix, we integrated them within the belt layers alongside the charging port, preventing charging while worn and enhancing overall safety.

A Dynamic Mechanism Designed from Within

One of the project’s key technical aspects was the development of the dynamic pressure-reduction system. This mechanism needed to adapt to body movements to provide constant relief without compromising comfort. We prioritized an approach focused on reliability and ease of manufacturing. This strategy enabled us to design a robust functional core, naturally adaptable to real-world usage conditions.

Ergonomics

and Morphology

Once the mechanisms were validated, we focused our work on the ergonomic optimization of the prosthesis, studying shapes, volumes, and contact areas to ensure a natural adaptation to different body types while maintaining a high level of performance. Resulting from extensive research, this development is now accessible to the general public, offering an innovative solution for lumbar disorders.